Better Solar Starts Here with Unirac’s UL 3741

SHARE THIS:

Why is Rapid Shutdown Important?

Safety is a fundamental concern in any solar installation, and rapid shutdown is an advanced critical-safety feature that quickly de-energizes conductors in a PV array during emergencies such as flooding or fires. By disabling the power of a solar array, rapid shutdown standards protect our firefighters, first responders, and maintenance personnel from electrical hazards during emergencies. By mitigating the risk of electrocution, these systems ensure maximum protection when immediate action is necessary.

What is UL 3741?

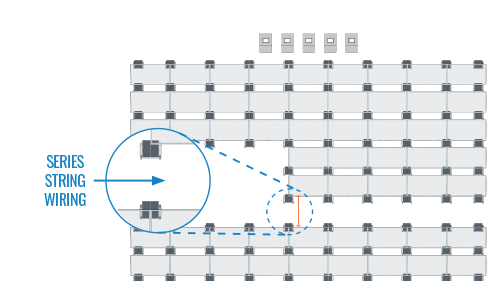

UL 3741 is a data-driven safety standard developed to provide an alternative to Module-Level Power Electronics (MLPEs) for rapid shutdown on commercial flat roofs. While MLPEs, like microinverters and solar optimizers, have been widely used to comply with rapid shutdown requirements, UL 3741 offers a streamlined approach that caters specifically to the needs of large-scale commercial installations.Why Should You Care?

UL 3741 matters because it protects our first responders. As an alternative to MLPEs, UL 3741 also provides a more flexible and cost-effective solution for achieving rapid shutdown compliance. By integrating UL 3741 into your solar projects, you can:

- Enhance Safety: Ensure the safety of first responders and maintenance teams by adhering to stringent safety standards.

- Save Money: Reduce the need for additional MLPEs, lowering overall system costs.

- Streamline Installations: Simplify the design and installation process with a wide array of approved inverter combinations.

Ease of Operations & Maintenance

One of the key advantages of UL 3741 is the ease of operations and maintenance (O&M) compared to MLPEs. UL 3741 reduces the number of DC-to-DC connection potential failure points over the 25-year lifespan of the system. This translates to fewer maintenance visits, lower repair costs, and more reliable system performance over time, making UL 3741 the preferred choice for long-term sustainability.

The Unirac Advantage

Unirac is proud to prioritize safety, our first responders, and our customers. This is why Unirac offers the most extensive portfolio of flat roof, flush-mounted or tilt-up systems, and inverter combinations approved under UL 3741. Whether you’re working on a residential project with the Tesla PV Inverters, Tesla Powerwall, or a commercial installation with rail or flat roof systems, Unirac has you covered. Our solar mounting systems are designed to be application agnostic, offering compliance via both UL 3741 and MLPEs to suit your specific needs and unique use case

Comprehensive Support for Commercial Designs

Our dedicated Commercial & Industrial (C&I) team is here to help optimize your commercial designs and provide the support you need when working with AHJs, developers, or project owners. We are committed to guiding you through the UL 3741 path, ensuring that your projects not only meet safety standards but also achieve the highest levels of efficiency and cost-effectiveness.

Trust Unirac for Your Solar Mounting Solutions

At Unirac, we believe that Better Solar Starts Here. With our expertise, extensive product portfolio, and commitment to safety and efficiency, we are your trusted partner for photovoltaic (PV) mounting solutions. Let us show you the benefits of UL 3741 and why Unirac is the right choice for your next project.

For more information on how Unirac’s UL 3741 can benefit your solar installations, contact us today and discover why Better Solar Starts Here.